Ash and Slag Resource Recycling

Ash and Slag Resource Recycling

In recent years, the management of incineration bottom ash and fly ash has emerged as a significant environmental issue. To promote sustainable resource utilization, the government has implemented relevant policies and measures to ensure the proper treatment and recycling of waste.

Background and Current SituationIncineration bottom ash and fly ash are residues left after the incineration of household waste and are classified as household waste. After pretreatment and impurity removal, incineration bottom ash can be converted into a material known as "incineration recycled aggregate," which is used in road base construction. Since 2002, the Environmental Protection Administration (now the Ministry of Environment) has been promoting the recycling of incineration recycled aggregate by establishing usage regulations and management systems to ensure its safe application and to protect the environment.

Currently, most incineration fly ash is stabilized and disposed of in landfills, with treatment required to reduce its hazardous components to below hazardous waste standards before final disposal. There are also experimental projects exploring the reuse of incineration fly ash, where it undergoes a pre-washing process and is subsequently used in cement production or high-temperature smelting industries. In these processes, heat is utilized to neutralize the hazardous components of the fly ash.

To promote resource recycling, the Environmental Management Administration has established an incineration recycled aggregate policy based on five core principles: "autonomous bottom ash treatment," "complete aggregate recycling," "government accountability for recycling," "priority use in government construction projects," and "enhanced aggregate quality and productization." Through evaluations and recommendations, the Environmental Management Administration supports local governments in achieving these policy objectives.

Counties and cities lacking sufficient capacity for autonomous bottom ash treatment are encouraged to develop long-term plans for establishing independent treatment facilities.

The principle is to ensure the immediate recycling of all aggregate produced annually. If the recycling rate falls below 100%, a review and enhancement of the promotion system should be conducted.

Local governments are responsible for aggregate recycling. If any contract subverts this responsibility, it should be reviewed and corrected.

Aggregate use should be prioritized for government construction projects and those where environmental evaluations are autonomously conducted by environmental protection agencies. Its use in private sector projects should be minimized.

Aggregate development should focus on "quality enhancement and diversified productization."

For incineration fly ash, the objective is to ensure proper treatment and recycling. The long-term goal is to allow widespread application through pre-washing; the short-term goal is to reduce fly ash generation, optimize the use of existing facilities, and minimize landfill demand.

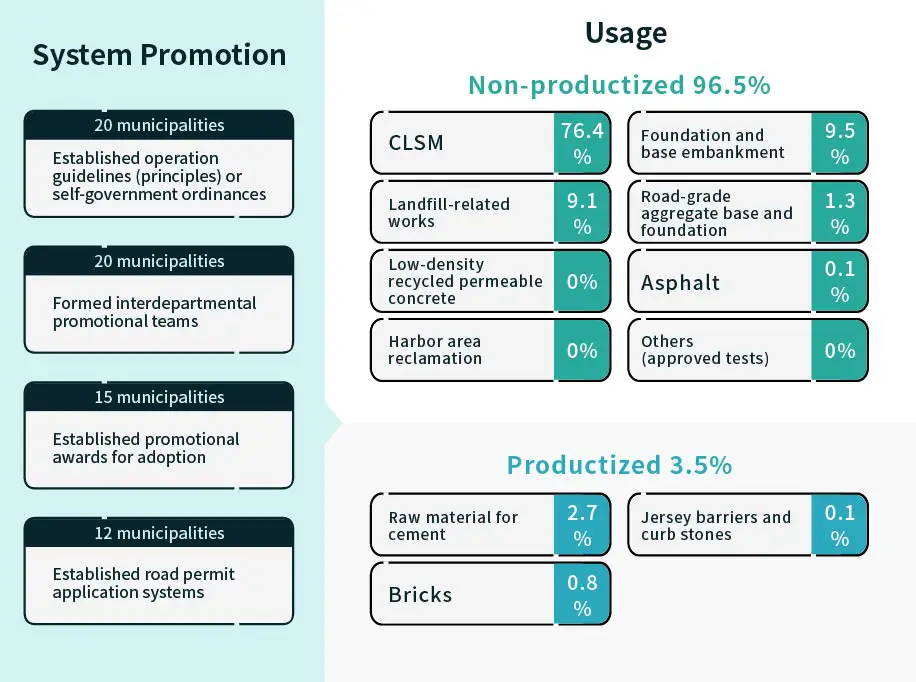

Work Development and ActionsTo establish a sound recycling system for incineration recycled aggregate, since 2017, after years of the Environmental Management Administration promoting and collaborating with local governments, counties and cities have implemented systems that include developing operational regulations, enacting local ordinances, establishing promotional task forces, and creating certification and incentive programs. These measures rigorously ensure the quality of incineration recycled aggregate, providing greater assurance for users and the public.

Additionally, to enhance the quality of incineration recycled aggregate, the administration has assisted and guided local governments in establishing public bottom ash treatment facilities. Taipei City, New Taipei City, Taoyuan City, Tainan City, Kaohsiung City, Yilan County, and Chiayi City have completed these facilities, in line with the "autonomous bottom ash treatment principle" policy goal of self-production and self-sales.

For incineration fly ash, the administration encourages local governments to conduct recycling trial projects and provides guidance in establishing fly ash washing facilities. As a result, the recycling rate has significantly improved to over 10%.

According to statistics, large-scale incinerators nationwide produced approximately 823,000 tons of incineration bottom ash in 2024, accounting for around 13.6% of the total incinerated waste. After treatment by recycling organizations, about 759,000 tons of incineration recycled aggregate were produced. Through government-promoted aggregate recycling application in public works, including the use of previously stored aggregate, 821,000 tons of incineration recycled aggregate entered the recycling system in 2024 achieving a recycling rate of 100% for the year.

The incineration recycled aggregate was mainly used in road construction projects, with controlled low-strength material(CLSM)accounting for about 76.4%, base embankment fills for approximately 9.5%, and the remainder applied in landfill-related engineering and as raw material for cement.

Historical Data Graph for Bottom AshNote: in cases where processed quantity exceeds generated quantity, counties and cities process not only the generated bottom ash from the current year but also additional quantities landfilled or stockpiled from previous years.

Historical Data Graph for AggregateNote: in cases where recycling quantity exceeds generated quantity, counties and cities recycle not only the aggregate from the current year but also additional quantities stockpiled from previous years.

In 2024, the amount of incineration fly ash generated was approximately 184,000 tons, accounting for about 2.9% of the total incinerated waste. Approximately 24,000 tons, or 13%, were reused. The remaining incineration fly ash underwent stabilization treatment before being landfilled or temporarily stored. Recycled fly ash typically undergoes a washing process to reduce chlorine content , after which it is used as process material or calcium-based alkali agents in the cement and high-temperature smelting industries.

ConclusionThrough the effective recycling of incineration recycled aggregate and incineration fly ash, reliance on natural resources is reduced, environmental pollution is minimized, and the goal of resource recycling is achieved. The government will continue to actively promote relevant policies and measures to further protect the environment and facilitate circular economy development.

- Data Source: Division of General Waste Management

- Publish Date: 2024-08-27

- Update Date: 2025-05-23

Related Topics

Related Topics